The MTU2000/4000 series diesel engines, designed and launched by MTU of Germany (now renamed Rolls-Royce Power Systems, but still using the MTU brand for its products) at the end of the last century, are widely used in high-speed vessels worldwide due to their high power density, compact structure and excellent reliability.

In addition, due to its low fuel consumption rate and excellent performance that meets various current emission standards, it has also been widely applied in the civilian sector, especially in various high-performance ships.

Since the beginning of this century, various ship design institutes in our country have adopted these two series of engines in large quantities for various civilian purposes, starting from military, military trade and government service vessels such as those for border defense and customs.

These two series of engines are still among the most advanced models in the world at present.

Due to the characteristics of their structure and performance, when these two types of engines are adopted as the main propulsion engines in ship design, there are some technical features that require special attention.

Understanding and mastering these characteristics is of great benefit to better exerting the performance of diesel engines and correctly completing the design work of ships.

I. Characteristics of Marine Engine Design

1. Model selection

The selection of the model is the first problem that the marine engineer encounters.

The MTU diesel engines have a complex range of models and numerous variants. There are strict regulations on which model should be selected for specific applications.

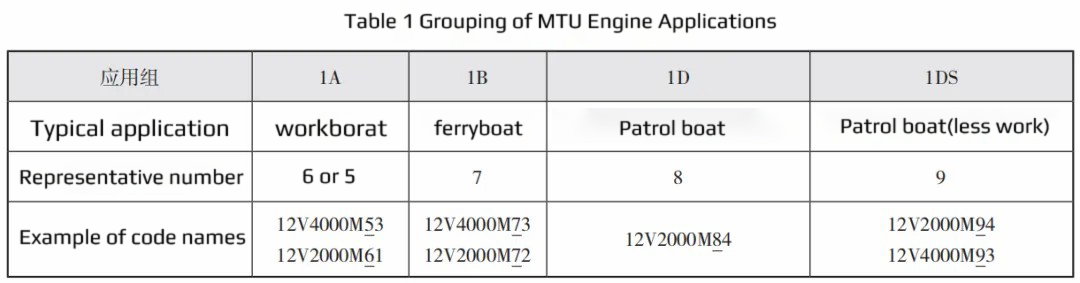

The MTU marine diesel engines are classified into several groups (1A, 1B, 1D, 1DS) based on different applications. The specific application scope of each group is shown in Table 1.

Due to the different purposes of various ship types, the working requirements and intensities of their main engines also vary. Therefore, the models of each application group are actually modified versions of the same basic model based on different uses.

The typical vessel type in Group A is various-purpose work vessels. The main engine operation characteristics of these vessels are that they operate continuously for a long time, have a large number of working hours each year, and often need to operate at maximum power.

Therefore, the required major overhaul interval time is set to be longer in hours to ensure that there are sufficient working years within one major overhaul period.

Therefore, among the four variants of the same model, the 1A group has the lowest maximum power among them.

The fixed-busier ferry is the representative vessel type of Group 1B. Its operation feature is that the power gradually increases when leaving the dock, operates at full power after entering the route, and gradually reduces to the maximum power and then stops when approaching the dock.

Therefore, its main unit can operate at its maximum power for a long time, but it usually only works for 8 to 10 hours a day, and remains in a shutdown state for the rest of the time.

1D and 1DS are the patrol boat and yacht application groups. Their characteristic is that the maximum power usage time is short, and most of the time they use the cruising power. The annual working time of the engine is also short. Therefore, among the four variants, the rated power for the application of 1DS is the highest.

Even though the major overhaul period is relatively short when measured by the total working hours, it can still be used for several years before requiring a major overhaul.

Therefore, in principle, the type of the machine should be selected within the corresponding application group based on the purpose of the vessel; otherwise, it will lead to early damage of the engine.

For instance, if the 12V2000M94 engine from the 1DS group is used as the main engine for a passenger ship, although the power can meet the requirements, the engine will eventually be overloaded and damaged due to the excessive proportion of time it operates at its maximum power.

If the models of Group 1B are used on patrol boats, since they have a lighter load than passenger ships, it is permissible.

The modifications of MTU diesel engines are very complex. Generally, one model can be used for one specific purpose. To be on the safe side, during the model selection stage, clarifications should be obtained through consultation.

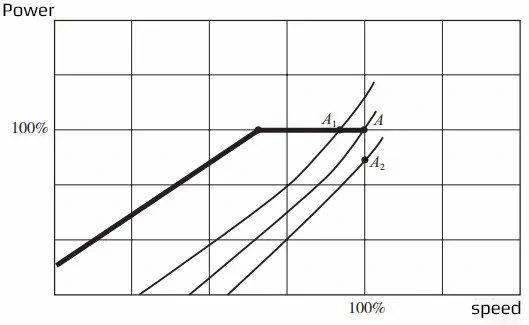

2. Power Calibration and Usage

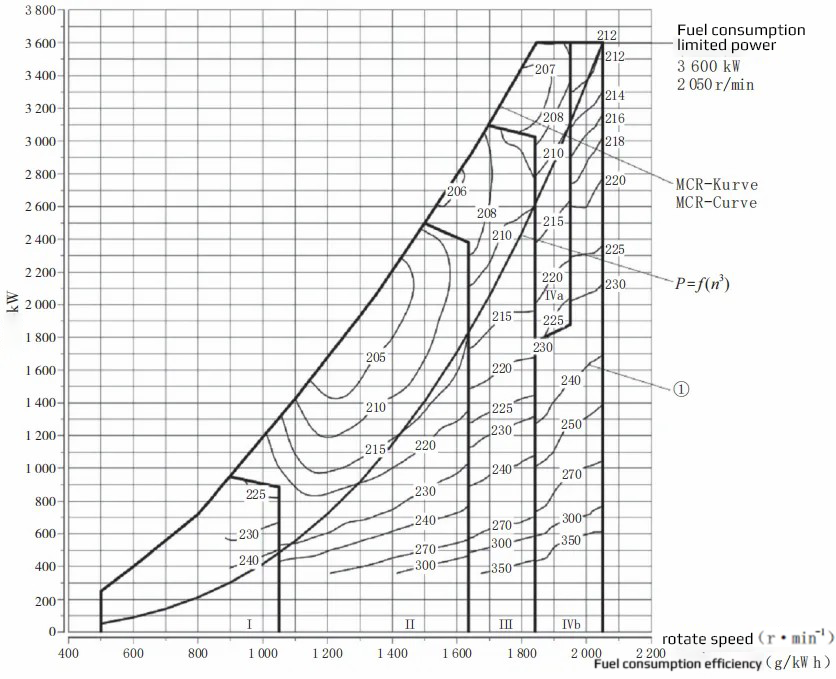

Only by understanding the regulations for power calibration can one use the power correctly.

Since the early 1990s, MTU diesel engines have stipulated that all their main engines should be calibrated with the ISO’s ICFN power, which is the sustainable fuel consumption limit power as per the ISO standard.

Therefore, this is the maximum power that the engine can provide for use, and there is no possibility of exceeding it.

When a ship is required to have an overloaded power capacity, the rated power can only be reduced proportionally as the designed power.

In the 20th century, due to the regulations of our country’s ship inspection, such situations occurred frequently.

So, in fact, because this calibrated power can be continuously used, it results in a waste of the engine’s capacity.

At that time, the design unit, the Chinese Classification Society, and MTU Company often held consultations on individual cases in order to obtain the classification society’s approval for the calibrated power.

Then, in the high-speed ship regulations issued by the classification society in the 1990s, there was no longer a requirement for 110% overload power. Thus, when building ships according to this regulation, this kind of trouble was avoided.

Of course, for ships that insist on being constructed in accordance with the steel marine vessel specifications with overload power requirements, when there is a conflict with the rated power, it can still be resolved through negotiation.v

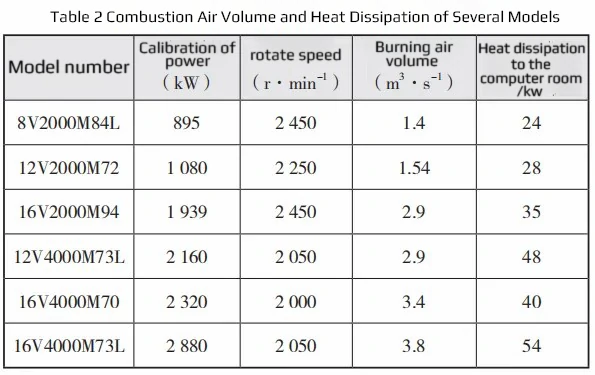

4. High combustion air volume and low cabin heat dissipation

The MTU2000/4000 engine is a highly pressurized engine, but it also has extremely high structural compactness. Therefore, the power output per unit engine displacement is much higher than that of ordinary engines, and the amount of combustion air required is also particularly large.

Table 2 presents the combustion air volumes for several models. When designing the engine (especially for the design where the combustion air is drawn from the engine room), special attention should be paid to this.

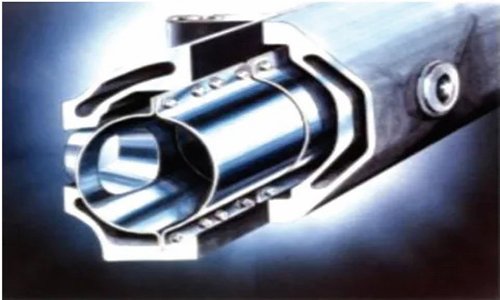

However, despite the extremely high power output of this engine, its heat dissipation capacity within the cabin is very low (as shown in Table 2). This is mainly attributed to its unique three-layered exhaust pipe design.

As shown in Figure 3, there is a cavity between the inner channel of the exhaust pipe and its outer wall, preventing the gas inside the pipe from coming into contact with the outer wall and thus blocking the transfer of heat.

The outer wall of the pipe has a lower temperature, which meets the requirements of ship inspection and also reduces the heat loss to the engine room. Therefore, the ventilation volume used for cooling the engine room can be significantly reduced.